3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects layer by layer from a digital design. Unlike traditional manufacturing, which often involves cutting, molding, or subtracting material, 3D printing builds objects additively, making it highly versatile, cost-efficient for small batches, and capable of producing complex shapes that were once impossible

Today, 3D printing is used in industries as diverse as healthcare, aerospace, automotive, fashion, construction, and education. From prosthetic limbs to airplane parts, and from rapid prototyping to full-scale houses, this technology is reshaping how products are imagined, designed, and manufactured.

In this guide, we’ll break down everything you need to know about 3D printing — its history, how it works, types of technologies, materials, software, real-world applications, and where it’s heading in the future. Whether you’re completely new or looking to sharpen your knowledge, this will serve as your go-to resource.

Introduction to 3D Printing / Additive Manufacturing

3D printing, often called additive manufacturing, is a way of creating solid objects directly from a digital design. Instead of cutting, shaping, or molding material like in traditional manufacturing, 3D printing works by adding material layer by layer until the final object takes shape. This idea of “adding” rather than “subtracting” is why it is called additive manufacturing.

The concept may sound technical, but at its heart, 3D printing is a very simple idea: a machine reads a design file from a computer and then builds that design in real life, one thin slice at a time.

What makes it different from traditional manufacturing?

Traditional manufacturing often relies on subtractive processes. For example, a block of metal might be cut, drilled, or milled until the desired part is left. This approach can waste material and limit the shapes that can be created. 3D printing takes the opposite approach. Because it builds from the ground up, it can produce shapes and details that would be impossible or too costly to achieve with older methods.

Everyday examples of 3D printing

Even if you have not noticed it, 3D printing is already part of daily life. Dentists use it to make crowns and aligners that fit each patient perfectly. Designers create custom jewelry and home décor with it. Students and hobbyists print small tools, toys, and replacement parts for broken items at home. In industries, companies use 3D printing for rapid prototypes, which are early models of a product made for testing before mass production.

Why it matters today

The strength of 3D printing lies in its flexibility. A single machine can produce something different every time, as long as it has the right design file. This makes it a technology that is shaping not only manufacturing but also medicine, education, and even construction.

History of 3D Printing

3D printing may feel like a modern breakthrough, but its roots go back more than 40 years. The story of how it developed shows how small scientific steps grew into a technology that is now changing industries worldwide.

The first invention in the 1980s

In 1983, an engineer named Chuck Hull created the first 3D printing process called stereolithography. This method used light to harden a liquid resin, forming objects layer by layer. Hull later founded a company called 3D Systems, which became one of the pioneers in the field. This was the first time that digital designs could be turned into real physical objects automatically.

Key milestones in the 1990s and 2000s

Soon after, other methods were invented. Selective Laser Sintering (SLS) used lasers to fuse powder materials, while Fused Deposition Modeling (FDM) melted plastic filament and laid it down in layers. For years, these methods were mainly used in research labs and by large companies, because the machines were expensive and protected by patents.

When several patents expired in the late 2000s, smaller companies and open-source communities were able to build their own versions. This led to a wave of innovation and falling prices.

Rise of consumer printers in the 2010s

By the early 2010s, 3D printers small enough to fit on a desk became available. Hobbyists, educators, and small businesses began to explore what could be made at home or in classrooms. The “desktop revolution” made 3D printing more visible to the public.

Industry adoption

At the same time, industries such as aerospace, automotive, and healthcare were adopting 3D printing for prototypes, custom parts, and even production-ready items. What began as an experiment in the 1980s had become a powerful tool across many fields by the 2010s.

How Does 3D Printing Work?

The best way to understand 3D printing is to look at it as a journey. A design starts on a computer, then goes through several stages until it becomes a physical object. Each stage plays an important role in making sure the final product looks and functions as intended.

Step 1: Creating the design (CAD software)

Everything begins with a digital model. This is often made in Computer-Aided Design (CAD) software, which is a program used to create 3D shapes on a computer. There are beginner-friendly tools like TinkerCAD, as well as professional ones like Fusion 360 or SolidWorks.

If you don’t want to design from scratch, there are also websites with ready-made models you can download. These models are saved in formats that 3D printers can understand.

Step 2: Converting to the right file (STL, OBJ, AMF)

Once the design is ready, it needs to be saved in a special format. The most common is STL, which stands for Standard Tessellation Language. It describes the surface of the 3D model in small triangles. Other formats include OBJ, often used for models with color or texture, and AMF, which can describe more complex details. These files act as the blueprint for the printer.

Step 3: Slicing the model

A 3D printer cannot read the design file directly. Instead, the file is processed through a slicer program. The slicer takes the 3D model and cuts it into many thin horizontal layers, like slicing bread. It also creates the instructions, called G-code, that tell the printer how to move, where to place material, and what speed or temperature to use.

Step 4: The printing process

Now the real work begins. The printer follows the instructions layer by layer. In an FDM printer, for example, a heated nozzle melts plastic filament and lays it down on the build surface.

Once a layer is complete, the printer adds another one on top. Slowly, the object rises until it is fully formed. Resin printers work similarly but use light to harden liquid resin instead of melting plastic.

Step 5: Post-processing the object

When printing is finished, the object is usually not ready to use right away. It may need cleaning, sanding, or curing under light to reach full strength. Supports, which are temporary structures printed to hold up complex shapes, may also need to be removed. Post-processing ensures the object looks neat and functions as intended.

Why “layer by layer” matters

The idea of building layer by layer is what gives 3D printing its strength. Unlike traditional methods, which are limited in the shapes they can cut or mold, this approach allows almost any geometry. Hollow parts, lattice structures, and even organic shapes can be created with little extra cost.

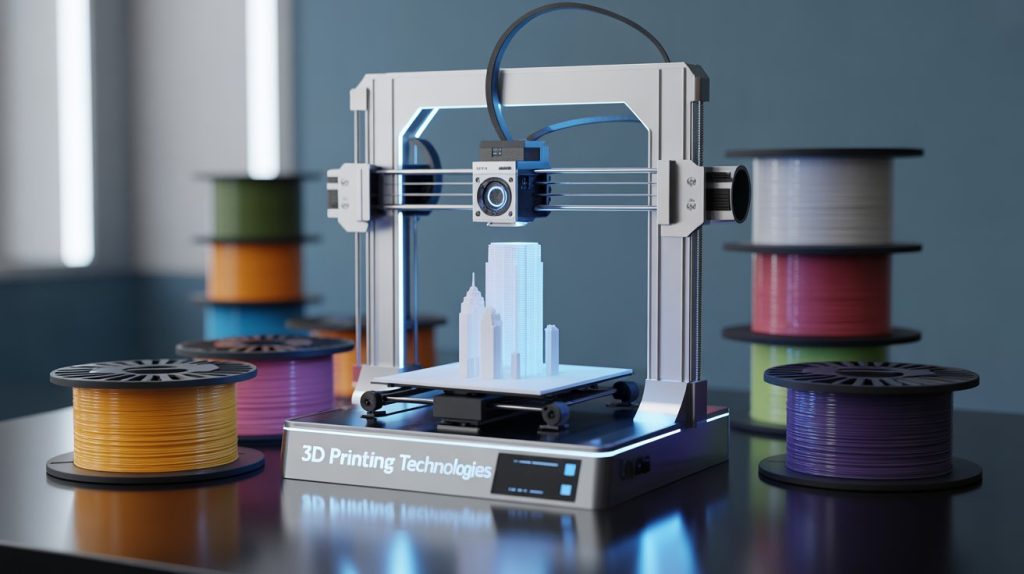

Types of 3D Printing Technologies

3D printing is not a single technology but a family of methods. Each one uses a different way of adding material layer by layer, and each has its own strengths and weaknesses. To understand which technology suits which purpose, let us look at the main categories.

FDM/FFF – Fused Deposition Modeling

The most common and affordable type of 3D printing is called Fused Deposition Modeling (FDM), sometimes also referred to as Fused Filament Fabrication (FFF). In this method, a plastic filament is heated and pushed through a nozzle, which lays the melted material onto the build surface in thin lines. The printer then adds one layer after another until the object is complete.

This is the type of printer most hobbyists and schools use, because the machines are relatively inexpensive and the materials, such as PLA or ABS plastic, are easy to find. FDM is excellent for prototypes, hobby projects, and functional household items.

SLA/DLP – Stereolithography and Resin Printing

Stereolithography (SLA) was the first 3D printing method ever invented. Instead of plastic filament, it uses a liquid material called resin. A light source — usually a laser or a projector in the case of Digital Light Processing (DLP) — hardens the resin layer by layer.

Resin printers are known for their very fine detail and smooth surface finish. They are often used for dental models, jewelry, miniatures, and other applications where precision matters. However, resin can be messy to handle, requires post-curing under ultraviolet light, and has higher material costs compared to filament.

SLS/MJF – Selective Laser Sintering and Multi Jet Fusion

Selective Laser Sintering (SLS) is an industrial method that uses a laser to fuse together powdered material, often nylon. Multi Jet Fusion (MJF), developed by HP, is a similar process but uses chemical agents and heat instead of just a laser.

Because the object is formed inside a bed of powder, there is no need for extra support structures. This means complex shapes, interlocking parts, and durable components can be printed directly.

These methods are widely used in industries like aerospace, automotive, and healthcare, where strength and reliability are critical. The downside is that the machines are expensive and require specialized environments.

Binder Jetting and Metal 3D Printing

Binder Jetting works by depositing a liquid binding agent onto a bed of powder, layer by layer, similar to how a 2D inkjet printer works. Later, the part may be sintered, which means heated to fuse the particles together.

This method is especially important for metal 3D printing. Instead of cutting or casting, metals like steel or titanium can be shaped directly. Metal 3D printing makes it possible to create lightweight parts with internal channels, often used in aerospace and medical implants.

The main challenges are cost, the need for advanced post-processing, and strict safety requirements when handling fine metal powders.

Choosing the right technology

Each type of 3D printing has its place. For personal use, FDM is often the starting point. For high detail, resin printing like SLA or DLP is better. For industrial strength and complexity, SLS and MJF are leading options. For specialized and high-performance parts, binder jetting and metal printing are unmatched.

Comparison Table

| Technology | Pros | Cons |

| FDM/FFF | Affordable, easy to use, wide material choice | Visible layer lines, lower detail, weaker strength |

| SLA/DLP | Very high detail, smooth finish, complex small parts | Resin is messy, post-curing needed, higher material cost |

| SLS/MJF | Strong parts, no supports needed, complex shapes possible | Expensive, industrial setup required |

| Binder Jetting & Metal | Can print metals, lightweight strong parts, advanced applications | Very costly, requires post-processing, safety concerns with powders |

3D Printing Materials

The type of material you choose for 3D printing is just as important as the printer itself. Each material behaves differently, has its own strengths and weaknesses, and is suitable for certain applications. Below is an overview of the main groups of 3D printing materials.

Plastics

Plastics are the most common materials in 3D printing. They are widely available and easy to work with.

- PLA (Polylactic Acid): A biodegradable plastic made from plants such as corn. It is easy to print, low-cost, and ideal for beginners. However, it is not very heat-resistant and may deform in hot conditions.

- ABS (Acrylonitrile Butadiene Styrene): Stronger and more heat-resistant than PLA. It is used for functional parts, but it requires higher printing temperatures and good ventilation due to fumes.

- PETG (Polyethylene Terephthalate Glycol): A good balance between PLA and ABS. It is tough, durable, and less prone to warping.

- Nylon: Flexible and strong, often used for mechanical parts. It absorbs moisture easily, so it must be kept dry.

- TPU (Thermoplastic Polyurethane): A rubber-like plastic that is flexible and elastic. It is great for phone cases, wearables, or gaskets.

Resins

Resins are used in SLA and DLP printers. They start as liquid and are hardened by light.

- Standard resin: Produces smooth, detailed parts, mostly for models or prototypes.

- Tough resin: Stronger and more impact-resistant, suitable for functional parts.

- Flexible resin: Mimics rubber-like qualities, useful for grips or seals.

- Dental resin: Specially designed for dental models, crowns, or surgical guides.

- Biocompatible resin: Safe for skin contact, often used in medical or wearable devices.

Metals

Metal 3D printing is more advanced but allows parts that are both strong and lightweight.

- Steel: Versatile and durable, used in tools and machinery.

- Titanium: Extremely strong yet lightweight, common in aerospace and implants.

- Aluminum: Lightweight and resistant to corrosion, useful in automotive and consumer products.

Composites

Composites are materials mixed with fibers to add strength.

- Carbon fiber reinforced plastics: Light but very strong, often used for drones or automotive parts.

- Glass fiber reinforced plastics: Less expensive than carbon fiber but still stronger than plain plastics.

Emerging Materials

New materials are being developed rapidly, expanding what 3D printing can achieve.

- Ceramics: Used for art, design, and even engineering components that need high heat resistance.

- Food-based materials: Chocolate, sugar, and dough are being 3D printed for culinary uses.

- Bio-inks: Special materials that contain living cells, used in experimental medical printing for tissues and organs.

Choosing materials wisely

The right material depends on what you want the final object to do. For simple models, PLA works well. For functional prototypes, PETG or ABS are better. For medical or aerospace applications, resins, metals, and composites open up more advanced possibilities.

3D Printing Software

No 3D printer can work on its own. To create an object, you need software that helps design the model, prepare it for printing, and finally send clear instructions to the printer. This process is supported by two main types of software: design tools and slicers.

CAD Software – Creating the Design

The first step in 3D printing is to make a digital model. This is done with CAD software, short for Computer-Aided Design. These programs allow you to build 3D shapes on a computer before they are printed.

- TinkerCAD: A free, web-based tool designed for beginners. It is simple, with a drag-and-drop interface, making it popular in schools and for hobby projects.

- Fusion 360: A professional tool from Autodesk that combines design, simulation, and engineering in one platform. It is widely used in product development and mechanical design.

- SolidWorks: Another professional-grade software often used in engineering and manufacturing. It is powerful for creating precise parts but has a steeper learning curve.

For artists or designers who care more about sculpting than engineering, software such as Blender or ZBrush is also used. These are better for creating organic shapes like characters, art pieces, or jewelry.

Slicer Software – Preparing the File

Once the design is finished, it cannot be sent directly to the printer. The file needs to be processed in a slicer program. A slicer takes the 3D model and breaks it into hundreds or thousands of thin horizontal layers.

The slicer also creates the instructions that guide the printer. These instructions are called G-code, which is a simple language that tells the printer where to move, how fast to go, what temperature to use, and when to extrude material. Without slicing, the printer would not know how to build the object.

Popular slicer programs include:

- Cura: A free and open-source slicer developed by Ultimaker. It is user-friendly and widely supported by many printers.

- PrusaSlicer: Originally made for Prusa printers but compatible with others. It offers a balance of simplicity and advanced features.

- Simplify3D: A paid slicer with powerful customization options. It is used by professionals who need fine control over print settings.

File Formats – STL, OBJ, and More

When you save a design, it must be stored in a file format the slicer understands. The most common is STL, which describes the surface of the model as many small triangles. OBJ is another format that can include colors and textures. AMF is less common but supports advanced features like curved surfaces and material information.

These files are then loaded into the slicer, which outputs G-code for the printer.

Beginner vs Advanced Tools

Not all software is created for the same audience. Beginners usually benefit from tools that are easy to use and forgiving. TinkerCAD and Cura, for example, allow new users to create and print with minimal setup.

On the other hand, advanced users and professionals need more control. Fusion 360 or SolidWorks can create parts with precise dimensions, while Simplify3D offers fine tuning for print quality. For research or industrial work, advanced slicers can even optimize material usage or predict how strong a printed part will be.

Why software matters

Good software makes the difference between a successful print and a failed one. A design tool that matches your skill level ensures you can model what you need without frustration. A reliable slicer ensures the printer has clear instructions. Together, these tools form the digital backbone of the 3D printing process.

Applications of 3D Printing

3D printing is now more than a way to make prototypes. It is transforming industries by creating parts, models, and tools that are custom, complex, or hard to produce in other ways. Below, you’ll find how different fields are using 3D printing to solve real-world challenges.

Medical – Prosthetics, Implants, Surgical Planning

In healthcare, dentists and surgeons use 3D printing to create prosthetics (artificial body parts like fingers or facial features), implants (like bone or joint replacements), and surgical models that help in planning operations.

For example, 3D printing of anatomic models was proposed and approved by Dept of Health, Abu Dhabi and included “3D models can be used to improve patient care, enhance patient and provider education, and facilitate surgical planning for complex injuries. Surgeons are uniquely positioned to utilize 3D printing and heightened awareness of the methodology of this novel technology is advantageous. Complex malunion reconstructions are distinct and require a high degree of preparation when considering intraoperative approaches”. Ref: Dept of Health, Abu Dhabi [PDF]

In the UK, the Bristol 3D Medical Centre (part of the NHS) uses 3D scanning and printing to make custom prosthetic noses, ears, and other parts. The technology allows faster, accurate, and less intrusive solutions—for example, scanning a patient’s face instead of using messy plaster casts. Ref: The Times, UK

Surgeons also rely on 3D-printed anatomical models for pre-surgical planning. For instance, models based on CT or MRI scans help them practice before a real operation. Studies show such models improve precision and can reduce risks. Ref: BTRT [Published July, 2023]

Aerospace & Automotive – Lightweight Parts, Prototyping

In the automotive and aerospace sectors, 3D printing helps create parts that are lighter, strong, and often more efficient than traditionally made ones.

Airbus incorporated over 1,000 3D-printed components into its A350 aircraft model, GE Aviation printed a helicopter engine with 16 parts replacing the original 900, achieving a weight reduction of 40% and cost savings of around 60%. Ref: Wikipedia

Automakers like Audi use 3D printing for interior panels and production tooling, A notable example: The Czinger 21 supercar is largely 3D-printed, including chassis and body, assembled by robots for precision and speed.

Construction – 3D-Printed Houses, Sustainable Building

Construction is embracing 3D printing to build faster, more affordable, and often more durable structures.

In Texas, the Zuri Gardens development near Houston includes 80 energy-efficient homes 3D-printed with concrete. These homes resist flooding, heat, and mold and cost less in labor and materials. Ref: New York Post [Published on Sep. 6, 2025]

Luyten 3D, in collaboration with UNSW in Australia, built the first 3D-printed home that met building codes in the Southern Hemisphere. The “Heptapod” took just two days to print and saved up to 80% in labor costs.

Historic and global efforts such as Habitat for Humanity printed homes quickly and cost-effectively. One house in Virginia was 3D-printed in 28 hours, saving 15% per square foot. Another in Arizona used 80% 3D-printed concrete despite extreme heat.

Consumer Products – Fashion, Furniture, Home Gadgets

3D printing allows designers to create one-of-a-kind jewelry, custom furniture pieces, or clever home gadgets with complex designs that would be hard to produce otherwise.

While specifics may vary, brands are increasingly leveraging flexible modeling tools to bring personalized or limited-edition goods to life (e.g. bespoke lighting fixtures, intricate design objects). These uses continue to grow across artisan and retail spaces.

Education & Research – Hands-on Learning, Lab Work

In schools and labs, 3D printing offers a hands-on way to learn design, science, and engineering concepts by turning ideas into physical models.

Students can print models of molecules, historical artifacts, or mechanical parts to explore complex systems up close. 3D-printed replicas of human anatomy help medical students practice and understand, making learning more interactive and engaging.

Research teams also use 3D-printed tools to prototype experimental devices, test materials, and explore new manufacturing approaches in a fast, iterative way.

Benefits and Limitations

3D printing offers several advantages that make it stand out from traditional manufacturing, but it also comes with challenges. Understanding both sides gives a realistic picture of what the technology can and cannot do.

Benefits

Customization: One of the strongest benefits is the ability to create custom items at no extra cost. A prosthetic limb, for example, can be shaped to perfectly fit an individual patient. The same applies to dental aligners or customized phone cases.

Speed for prototypes: Traditional manufacturing often requires molds or tooling that can take weeks to prepare. With 3D printing, a design can go from computer to physical model within hours. This makes it invaluable for product development, where quick feedback and improvements are critical.

Cost savings in prototyping: For small runs or prototypes, 3D printing is usually cheaper than setting up full-scale production. It avoids the cost of molds and specialized machines.

Complexity at no extra cost: A complex design that would be difficult or impossible to make with standard methods can often be printed as easily as a simple one. Hollow structures, internal channels, or lattice frameworks are achievable without extra difficulty.

Limitations

Not yet ideal for mass production: While 3D printing is fast for single items or small batches, it is still slower than traditional manufacturing for large-scale production.

Material strength limits: Many printed plastics are not as strong or durable as materials shaped by molding, forging, or machining. Metals and composites improve strength, but these options are costly.

High cost of industrial machines: Entry-level 3D printers are affordable, but machines capable of producing industrial-grade parts with consistent quality are expensive and often require specialized environments.

In short, 3D printing is a flexible and powerful tool, but it is best suited for prototypes, small batches, and custom solutions rather than large-scale production today.

Future of 3D Printing

3D printing is still evolving, and its future looks promising as new trends shape the industry.

Bioprinting

Researchers are developing bioprinting, which uses special materials mixed with living cells, sometimes called bio-inks. The aim is to print tissues or even entire organs for medical use. While still experimental, it shows how 3D printing could one day transform healthcare.

AI and Smart Printing

Artificial Intelligence (AI) is being used to make printers smarter. AI can analyze print quality in real time, predict errors before they happen, and suggest design improvements. This combination of AI and 3D printing could make the process more reliable and efficient.

Sustainability and Recycling

3D printing can reduce waste compared to traditional manufacturing, since it uses only the material needed for the part. New research is exploring printers that use recycled plastics or biodegradable materials. In construction, printed houses made from sustainable concrete mixes can reduce the carbon footprint of buildings.

Distributed Manufacturing

Another trend is distributed manufacturing. Instead of producing goods in one central factory and shipping them worldwide, 3D printers could allow local production near the point of use. This reduces shipping costs and delays, and provides more flexibility in supply chains.

Predictions for the market

For consumers, 3D printing will likely remain a tool for hobbyists, small businesses, and education, with desktop printers becoming more affordable and user friendly. For industry, the growth will be in aerospace, healthcare, and construction, where high-value custom parts and materials justify the investment.

Role in Industry 4.0

Industry 4.0 refers to the integration of digital technologies into manufacturing. 3D printing fits into this vision as a flexible, on-demand production method that complements robotics, automation, and data-driven decision making.

The future of 3D printing is not about replacing all traditional methods but about adding new options. It is most powerful when combined with other modern technologies to create faster, smarter, and more sustainable production systems.

Safety & Best Practices

Like any manufacturing tool, 3D printers require safe handling. Following a few best practices helps protect both users and machines while ensuring consistent results.

Ventilation for resin and filament printing

When plastics such as ABS are melted in filament printers (FDM), they can release fumes that may irritate the lungs if used in poorly ventilated spaces.

Resin printers also produce odors and may release small particles during curing. It is best to use 3D printers in a well-ventilated area, ideally with a small fan or air purifier nearby. Some professional setups even include enclosures with built-in filters.

Handling materials safely

Resins, especially in liquid form, should never come into direct contact with skin. Wearing simple protective gloves is recommended when pouring or cleaning resin.

Likewise, cleaning agents such as isopropyl alcohol, which are used to wash resin prints, should be handled with care. For filament printing, spools of plastic should be stored in dry containers to prevent moisture absorption, which can affect print quality.

Maintenance of machines

Regular maintenance improves both safety and performance. Nozzles and print beds should be cleaned to avoid buildup of material. Loose screws, belts, and rails should be checked occasionally to keep movements precise. For resin printers, the resin vat and build plate need gentle cleaning after each session.

Keeping the machine dust-free and following the manufacturer’s service guidelines extends the printer’s life and reduces failures.

By maintaining good ventilation, handling materials responsibly, and caring for the printer itself, users can enjoy safe and reliable 3D printing over the long term.

Conclusion

3D printing has moved from being a niche experiment to becoming a practical tool across industries and homes. Its ability to build objects layer by layer from digital designs opens possibilities that traditional manufacturing cannot easily achieve. From medical implants tailored to a patient, to lightweight aircraft components, to affordable housing, the range of uses continues to grow.

What makes 3D printing matter today is not only the speed and cost savings for prototypes, but also the freedom to create complex designs, the ability to customize without extra cost, and the opportunity to produce locally. These qualities make it an important part of modern manufacturing and education, and a stepping stone toward more sustainable ways of making things.

This guide is just the beginning. To explore further, you can read our detailed guides on technologies, materials, software, and industry applications. You can also use our tools and resources to compare options, learn best practices, and keep up with new trends in 3D printing.

Guide Categories

Guide Categories

Quick Poll

Quick Poll